Working principle

After the wet material is put into the dryer, the plate-spreader is uniformly distributed in the inner tube, and the material is uniformly distributed and dispersed in the dryer, and is in full contact with the cocurrent (reverse flow) hot air, which accelerates the drying and heat transfer. Pass to the driving force. During the drying process, the material can be regulated to move to the other star discharge valve of the dryer to discharge the product under the action of the tilting plate and the hot air flow.

Adapt to the material

◎ Chemicals, mines, metallurgy and other industries have large particles and dry materials with significant specific gravity, such as: mines, blast furnace slag, coal, metal powder, phosphate fertilizer, and ammonium sulfate.

◎For the drying of powder and granular materials with special requirements, such as: HP foaming agent, distiller's grains, light calcium carbonate, activated clay, magnetic powder, graphite, and dregs.

◎Requires low-temperature drying, and large batches of continuous drying materials.

Performance characteristics

◎ Tumble dryer has a high degree of mechanization and large production capacity.

◎ The resistance of the fluid through the cylinder is small and the function consumption is low.

◎ The adaptability to material properties is relatively strong.

◎ stable operation, low operating costs, and good product drying uniformity.

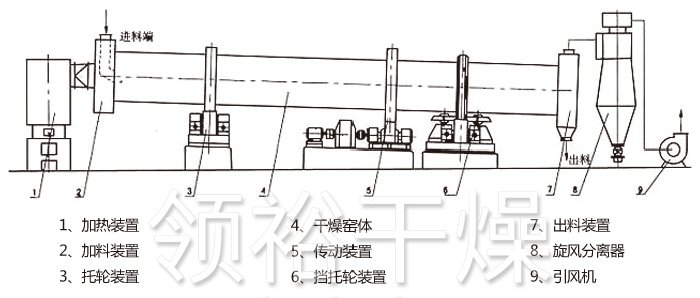

Schematic

Technical specifications

| Model | Direct heating downstream | Direct heating downstream | Direct heating countercurrent | Direct heating countercurrent | Composite heating | Composite heating |

| Material type | Ore | HP Foaming agent | Blast furnace slag | Thiammonium | Phosphate fertilizer | Coal |

| Processing capacity(kg/h) | 1000 | 466 | 15000 | 20000 | 12000 | 5000 |

| Water content(%) | 30 | 13 | 6 | 1.5 | 5 | 6.5 |

| Final moisture content(%) | 15 | 0.3 | 1 | 0.1 | 0.1 | 0.1 |

| The average particle size(mm) | 6.5 | 0.05 | 4.7 | 0.5-1.7 | 0.5 | 5 |

| Heavy material accumulation(kg/m3) | 770 | 800 | 1890 | 1100 | 1500 | 750 |

| Hot air volume(kg/h) | 3900 | 5400 | 10750 | 9800 | 6500 | 16000 |

| Inlet gas temperature(oC) | 600 | 165 | 500 | 180 | 650 | 570 |

| Material outlet temperature(oC) | 42 | 100 | 70 | 80 | 75 | |

| heating method | Gas | Steam heating | heavy oil | Coal hot stove | Heavy oil | Heavy oil |

| Loading factor | 6.3 | 7 | 7.5 | 7.8 | 18 | |

| Rotating speed(rpm) | 4 | 4 | 3.5 | 3 | 4 | 2 |

| Tilt | 0.04 | 0.005 | 0.03 | 0.05 | 0.05 | 0.043 |

| Copy board number | 12 | 24 | 12 | 22 |

Inside the inner tube8 Inside the inner tube16 |

6 12 |

| Dryer diameter(m) | 2.0 | 1.5 | 2 | 2.3 |

Outer tube2 Inner cylinder0.84 |

Outer tube2.4 Inner cylinder0.95 |

| Dryer length(m) | 20 | 12 | 17 | 15 | 10 | 16 |

| Driving power(kw) | 22 | 7.5 | 15 | 11 | 11 | 15 |

Working principleThe tumble dry…

Product descriptionThe wet mate…

Product descriptionThe product …

Working principleThis machine i…

Product descriptionThe disc con…

QG series pulse air dryerProduc…