Product description

Spray drying is a relatively widely used process in the liquid process forming and drying industries. It is particularly suitable for the production of powdery, granular solid products from solutions, emulsions, suspensions and pasty liquid raw materials. Therefore, spray drying is a very desirable process when the finished product particle size distribution, residual moisture content, bulk density, and particle shape must meet exacting standards.

Working principle

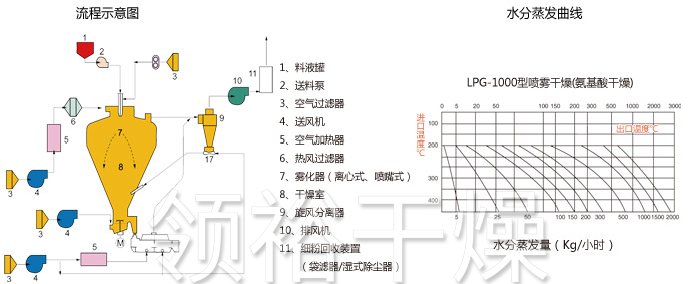

The air is filtered and heated into the air distributor at the top of the dryer. The hot air spirally enters the drying chamber. The feed solution is passed through a high-speed centrifugal atomizer at the top of the tower body, and (rotated) is sprayed into very fine mist-like liquid beads, and in contact with the hot air in parallel can be dried into a finished product in a very short time. The finished product is continuously output from the bottom of the drying tower and the cyclone separator, and the exhaust gas is exhausted by the fan.

Performance characteristics

◎Drying speed is fast, the surface area of material liquid is greatly increased after atomization. In hot air current, 95%-98% of water can be evaporated instantaneously, and the drying time is only a few seconds. It is especially suitable for the drying of heat-sensitive materials.

◎ The product has good uniformity, fluidity and solubility, and the product has high purity and good quality.

◎ The production process is simplified and the operation and control are convenient. For liquids with a moisture content of 40-60% (up to 90% for special materials), the liquid can be dried once into a powdered product, without crushing and screening after drying, which reduces production processes and increases product purity. The product particle size, bulk density and moisture content can be adjusted within a certain range by changing the operating conditions, and the control and management are very convenient.

Adapt to the material

Chemical industry: Sodium fluoride (potassium), basic dye pigments, dye intermediates, compound fertilizers, formaldehyde silicic acid, catalysts, sulfuric acid agents, amino acids, white carbon black, etc.

Plastic resin: AB, ABS emulsion, urea formaldehyde resin, phenolic resin, adhesive (urea) formaldehyde resin, polyethylene, polyvinyl chloride and so on.

Food Industry: Fat-enriched milk powder, Taro, cocoa powder, milk replacer, blood powder, egg white (yellow), etc.

Food and plants: oats, chicken juice, coffee, instant tea, spices, protein, soybeans, peanut protein, hydrolysates, etc.

Sugars: corn syrup, corn starch, glucose, pectin, maltose, potassium sorbate, etc.

Ceramics: Alumina, tile materials, magnesium oxide, talcum powder, etc.

Technical specifications

| Model / Item / Parameter | 5 | 25 | 50 | 150 | 200-2000 |

| Inlet temperature | 140-350 Self-control | ||||

| Output temperature | 80-90 | ||||

| Moisture evaporation limit(kg/h) | 5 | 25 | 50 | 150 | 200-2000 |

| Centrifugal spray head drive form | Compressed air drive | Mechanical transmission | |||

| Speed limit(r.p.m) | 25000 | 18000 | 18000 | 15000 | 8000-15000 |

| Spray disk diameter(mm) | 50 | 120 | 120 | 150 | 180-240 |

| Heat source | Electricity | Steam + electricity | Steam + Electric, Fuel, Gas, Hot Air Furnace | ||

| Electric heating power cap(kw) | 9 | 36 | 72 | 99 | |

| Dimensions (length × width × height)(m) | 1.8×0.93×2.2 | 3×2.7×4.26 | 3.5×3.5×4.8 | 5.5×4×7 | According to the actual situation |

| Dry powder recovery(%) | ≥95 | ||||

Note: The amount of water evaporation is related to the characteristics of the material and the hot air inlet and outlet temperatures. When the outlet temperature is 90oC, the evaporation curve of its moisture is shown in the above figure (for selection reference). As the product is continuously updated, the relevant parameters are changed without prior notice.

Download Google

◎Liquid liquid name, physical properties: solid content (or water content), viscosity, surface tension, and pH.

◎ After drying, the powder capacity, allowable residual water content, particle size, allowable temperature upper limit.

◎ Production, daily opening hours.

◎ Available energy: steam pressure available, capacity, available for coal, oil, gas.

◎ Control requirements: whether the inlet and outlet temperatures need to be controlled.

◎Powder collection requirements: Whether or not to install a bag trap, the environment requires exhaust emissions.

◎ other special requirements.

Technical specifications

| Size | A | B | C | D | E1 | E2 | F | G | H | I |

| LPG-25 | 1290 | 3410 | 4260 | 1800 | 1200 | 1200 | 1000 | 1700 | 1300 | 1550 |

| LPG-50 | 1730 | 4245 | 5100 | 2133 | 1640 | 1640 | 1250 | 1750 | 1800 | 1600 |

| LPG-100 | 2500 | 5300 | 6000 | 2560 | 2100 | 2100 | 1750 | 1930 | 2600 | 1780 |

| LPG-150 | 2800 | 6000 | 7000 | 2860 | 2180 | 2180 | 1970 | 2080 | 3050 | 1960 |

| LPG-200 | 2800 | 6600 | 7300 | 3200 | 2300 | 2300 | 2210 | 2250 | 3050 | 2100 |

| LPG-300 | 2800 | 8000 | 8700 | 3700 | 2800 | 2800 | 2520 | 2400 | 3040 | 2250 |

Working principleThe tumble dry…

Product descriptionThe wet mate…

Working principleAfter the wet …

Product descriptionThe product …

Working principleThis machine i…

Product descriptionThe disc con…