Product description

The machine is fully enclosed and all parts are made of stainless steel. It is equipped with a three-stage purification device, and the filtered air is required to reach 100,000 grades. The cylinder and the top are equipped with a cold wall device, so that the wall temperature is < 80°C, and an air brush tower device is installed in the drying tower. The traditional Chinese medicine extract powder dried by this machine will not appear coking and metamorphic phenomena, greatly increasing the rate of powder collection (over 95%), and it will not produce mixed drug phenomenon and sticky wall phenomenon.

Working principle

The Chinese medicine extract high-speed centrifugal sprayer is the application of centrifugal spray drying technology in the drying of specific materials. It also uses a high-speed centrifugal atomizer to disperse the material into a mist, fully contact with the hot air, complete instantaneous drying, and form a powdery finished product. Drying device.

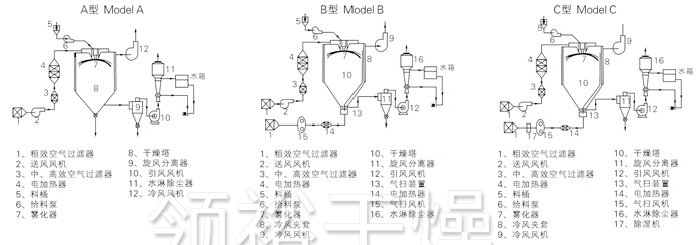

Schematic

Performance characteristics

◎ tower body with cold wind jacket;

◎ The tower body is equipped with automatic rapping device;

◎The tower body and pipelines are equipped with quick opening cleaning holes and drain holes;

◎ can be equipped with automatic control thermostatic feeding tank;

◎ can be equipped with manual high pressure washing tower accessories;

◎ The part in contact with the material is made of stainless steel (or made of stainless steel);

◎Two-stage cyclone dust removal device or one level

◎ cyclone dust collector and wet dust collector;

◎Inlet air temperature realizes automatic control and continuous device.

◎ can be equipped with air sweep device.

Technical specifications

| Model | ZLPG-15 | ZLPG-20 | ZLPG-25 | ZLPG-32 | ZLPG-38 | ZLPG-40 | ZLPG-47 | ZLPG-52 | ZLPG-58 | |

| Moisture evaporation | 5 | 10 | 25 | 50 | 80 | 100 | 150 | 200 | 300 | |

| Feed volume | 6-7 | 12-14 | 25-34 | 50-68 | 80-108 | 100-135 | 150-203 | 200-270 | 300-406 | |

| Finished product output | 1-2 | 2-4 | 4.8-7.2 | 9.2-14 | 14.8-22.4 | 18.4-28 | 28-42 | 36.8-56.4 | 55-85 | |

| Solid content of wet material | 18-25 | |||||||||

| Finished water content | 3-5 | |||||||||

| Electric power | 36 | 45 | 63 | 99 | 132 | 153 | 204 | 246 | 330 | |

| Heating source | Steam + Electricity | |||||||||

|

Product collection method And a collection efficiency |

One or two points collection: Collect bmx at once≥95% | |||||||||

| Automatic control instrument | Temperature and pressure automatic control, adjustment, interlock alarm | |||||||||

| Inlet air temperature | 150-200 | |||||||||

| Outlet temperature | 80-100 | |||||||||

| Dimensions(mm) | Length | 5000 | 5500 | 7000 | 8000 | 9800 | 11000 | 12200 | 14100 | 15000 |

| Width | 3000 | 3500 | 4000 | 5000 | 5700 | 6200 | 7000 | 7800 | 9000 | |

| Height | 4500 | 4600 | 5200 | 6500 | 7600 | 8100 | 9000 | 9850 | 11100 | |

Note:

★ The actual dimensions can be determined according to the actual situation of the customer. The above dimensions are for reference only.

★ The above evaporation is the upper limit of evaporation.

Working principleThe tumble dry…

Product descriptionThe wet mate…

Working principleAfter the wet …

Product descriptionThe product …

Working principleThis machine i…

Product descriptionThe disc con…