Product description

Extrusion granulation is a relatively new dry granulation process for producing compound fertilizers. Extrusion granulation In the early application of fertilizers to the granulation of potassium chloride, the granular (1-4 mm) potassium chloride required for blending fertilizer (BB fertilizer) was basically produced by extrusion. In recent years, extrusion granulation has been used in the production of compound fertilizers and it has been developed rapidly in China.

The form of extruding and granulating can be either roller or rim type. The roller squeezing is firstly pressed into large pieces and then broken into granules. This device has the advantages of large capacity, high grain strength, and low energy consumption. Roll extrusion is widely used abroad. The rim type is formed on the surface of the roll to have a grooving-type shape and is extruded into molding granules at a time. Low product strength sometimes requires the addition of a binder. Suitable for granular fertilizer such as organic fertilizer and compound fertilizer.

Working principle

The process principle of roller extrusion granulation is: the dry materials are agglomerated into compact and hard chunks (cake materials) under the action of pressure, which is called the extrusion process; the cake materials are then crushed and sieved to form pellets. Particle process. One of the effects of the extrusion is to squeeze out the air between the particles, and also to make the distance between the particles close enough to produce attractive forces such as van der Waals forces, adsorption forces, crystal bridges and embedded connections. Extruded pellets mainly rely on the strength of the particles formed by the forces between the molecules.

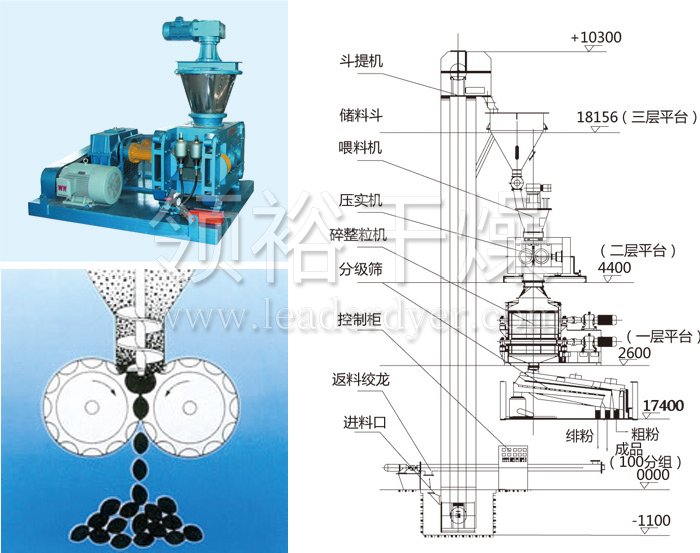

Schematic

Technical specifications

| Model | Roller center distance | Power |

| GZL-240 | 240 | 7.5-1.5 |

| GZL-360 | 360 | 22-45 |

| GZL-460 | 460 | 37-60 |

| GZL-580 | 580 | 45-90 |

| GZL-650 | 650 | 55-200 |

| GZL-730 | 730 | 90-315 |

Working principleThe agitated m…

Application areaThis machine is…

Working principleThe powder mat…

OverviewThe RL granulator uses …

Product descriptionThis unit is…

Product descriptionExtrusion gr…